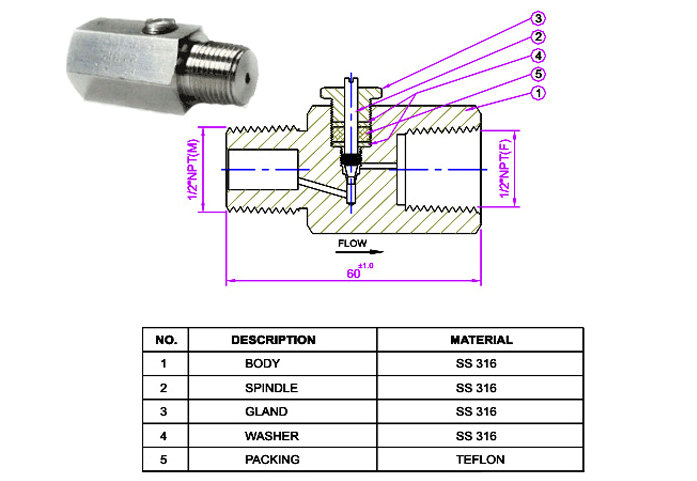

| Features : • Gauge Snubber fittings protects pressure gauges and instruments from system pressure surges and shock. Pressure damping (snubbing) is accomplished through the use of a porous sintered SS 316 element. When snubber is installed up stream from a pressure instruments , the response rate of the instrument is reduced and generally varies with the initial pressure drop across the porous metal element, and allows the instrument to smoothly come to line ressure. • Heat code traceability Application : • Refineries, liquid patroleum gas processing plant, petro-chemical plants, systems difficult to shur off due to solid contents dust, rust, dirt etc. Testing : • Pneumatic Seat test is performed at 1/4 of working pressure. • Hydrostatic shell test is performed at 1.5 times the working pressure. |

Technical Specification : • Size : 1/4"F x 1/4"M 1/2"F x 1/2"M 1/4"F x 1/8"M 1/2"F x 1/4"M 1/2"F x 3/8"M • End Connection : NPT, BSP, BSPT, or as per customer requirement. • Working Pressure : 5000 Psi (344Bar) • Temperature Rating : BRASS 400 Deg F (204 Deg C) SS 316 1000 Deg F (538 Deg C) • Material of construction : SS 316, SS 304, Brass, Monel • Optional Sour Gas service valves are available confirming to NACE Std. MR - 01 - 75 • All Snubbers are 100% Factory tested prior to shipment. |

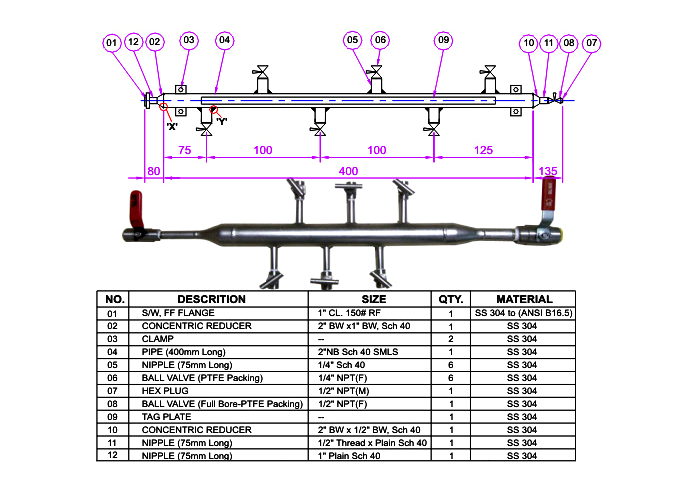

| Technical Specification : • Size : 1/2", 3/4", 1" NPT and Flange. • End connection : NPT,BSPT,Socket weld. • Working Pressure : 6000 Psi (413 Bar) • Temperature Rating : PTFE 450 Deg. F (232 Deg.C) Grafoil 700 Deg. F (371 Deg. C) Testing : • Pneumatic Seat test is performed at 1/4 of working pressure. • Hydrostatic shell test is performed at 1.5 times the working pressure. |

• Material of Construction : SS 316, SS 304, C.S.(seamless pipe) • Optional Sour Gas service valves are available confirming to NACE Std. MR - 01 - 75 • Stem packing : PTFE, Grafoil. • Orifice : Dia. 4.7 • All valves are 100% Factory tested prior to shipment. Lubrication : • Dye molly sulphide |

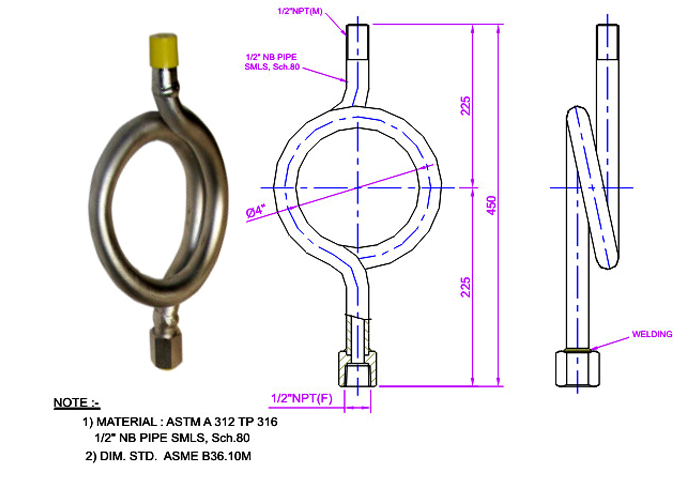

| • Syphons should be used in all steam applictions.pigtail steam syphons protect the instrument from damaging effects of direct exposure to high temperature steam. • To properly install and use a syphon with water and install the pressure gauge. The water will fill the lower half of the coil and will act as a protective barrier between the high temperature steam and the pressure gauge. • Optional IBR approval is offered, depending upon customer requirement Features : • Syphons are available with butt weld,socket and threaded end connections. Material : • SS 304, SS 316, C.S, Monel (Seamless Pipe) Note : • All syphons are 100% factory tested prior to shipment. |

| Condensate should not be confused with demineralized, de-ionized, make up, or softened water. When the condensate enters the boiler feed pump additionalchemicals are added and the product is now called boiler feed water. | |

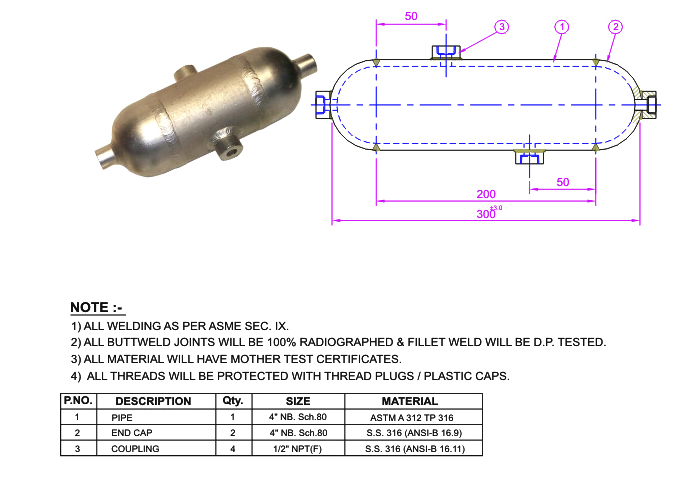

| Features : • Use as liquid or condensate traps, seal pots, vapor chambers and knockout pots. • All connectors are furnished with plstic plugs. • Chambers are made from seamless carbon steel pipe and weld caps. All pipe connections are 3000# half-couplings mounted on 90 Degree angle. Extra connections can be furnished upon customer request. • Heat code traceability • All welding as per ASME SEC. IX • All butweld joints will be 100% radiographed • Fillet weld will be D.P. tested. • All material will have mother test certificates. • All condensate pot will be hot dep galvanised. • All threads will be protected with dead plugs / plastic caps. • Piping code compliance ASME B31.1 and PED category I, Module - A. • Optional IBR approval is offered, depending upon customer requirement Application : • Refineries, liquid patroleum gas processing plant, petro-chemical plants, systems difficult to shur off due to solid contents dust, rust, dirt etc. |

Technical Specification : • Size : Pipe size 2",3",4" and larger size upon request. • Length : Pipe length 8",10",12" and larger length upon request. • Working pressure : 6000 Psig (413 Bar) • Material of construction : SS 316, SS 304, C.S., ASTM A 106 Gr B • Optional Sour Gas service valves are available confirming to NACE Std. MR - 01 - 75 • Pipe Schedule : 40, 80, 160, XX seamless pipe. • Chamber as per ISA RP3 • NPT as per ANSI B1.20.1 taper pipe thread 1/2" furnished. • Socket weld as per ANSI B16.11 • Butt weld as per ANSI B16.9 • All chamber are 100% Factory tested prior to shipment. Testing : • Hydrostatic shell test is performed at 1.5 times the working pressure. |

Technical Specification :

Technical Specification :

• Size : As per client requirement

• Maximum Working Pressure : 3000 PSIG The body and stinger are both constructed of chemical resistant alloys